Sheet Metal Fabrication Services

Tek-Neek have years of experience in the industry and are passionate about continually investing in the latest machinery, tooling and software. We will always advise on design, material, fixings, coatings and finish to ensure that you the customer get a high quality product within timescales, whilst maintaining a cost-effective solution.

Enquire NowOr call 01254 583008

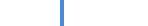

Design and development

We constantly try to improve existing products by drawing on our years of experience in the industry as well as looking at the latest technologies available. Simple redesigns or investment in tooling or machinery could improve the manufacturing process effectively saving time and therefore money.

If you do not have drawings of your products we can work from samples and produce full drawings using the 3D modelling software, Solidworks. We also offer a full design service so if your product is in the early design process we can take your sketches and ideas and working with our design team produce prototypes and hopefully get your ideas to market. Along with Solidworks we use the latest CAD/CAM software specific to the sheet metal industry.

CNC punching

Using Muratec Turret Punch Press we can offer high accuracy, high speed production of components competitively priced.

This is where the majority of components start to be processed. The turret punch is loaded with tools and the sheet material is punched to produce the components. We can punch a range of materials including mild steel, stainless steel, aluminium, coated metals, brass and copper from 0.6mm to 6mm.

Advantages of turret punch machines

- High speed

- Lower running costs than Laser machines

- The use of special tooling such as upforms, knock outs, countersinking, ribbing and thread forming

- Coated material such as pre-painted sheet, galvanised steel

- Read more about our CNC Punching Services here.

Our punching department includes

Muratec Wiedeman Motorum 2548

- Sheet size 2500 x 1300

- 800 hits per minute

- 44 tool stations plus multi tool

Muratec Wiedemann Motorum 2048

- Sheet size 2500 x 1250

- 700 hits per minute

- 25 tool stations

2 x Muratec Centrum 2500

- Sheet size 1250 x 1250

- 500 hits per minute

- 18 tool staions plus multi tool

Metal forming

After the components are punched on the turret punch they usually go the Press Brake department where the flat components are folded and formed.The machinery we use is very flexible and is suited for both large production runs and small batches and prototypes.

We have a range of press brakes of different size and tonnage.

- Bystronic 3100mm x 150 tonne

- Bystronic 3100mm x 100 tonne

- Bystronic 2500m x 100 tonne

- 2 x Bystronic 2500mm x 60 tonne

Welding

At Tek-Neek we offer both TIG and MIG welding and have dedicated and experienced staff that work to a high standard on all materials.

These include:

- MIG Welding – A quick semi-automatic process of fusing two pieces together. We use MIG welding on a huge range of jobs and products. From simple bracket work to gas fire burner boxes and pharmaceutical cabinets.

- TIG Welding – Although a slower process and more technically involving than MIG welding, TIG welding is used for high quality welds on critical joints where small, neat and precise welds are required.

- Spot Welding – A quick process of joining two items together used predominantly in the assembly of components

- Read more about our Welding Services here.

Assembly

Assemblies can range from simple electrical enclosures with hinges and locks to large balance flue gas fire assemblies with other 30 components that using gaskets and sealers to create an air tight sealed unit. We can have offer a service of packaging and distribution to suit your needs.

We have a designated Assembly area within our workshop where we use a wide range of processes.

These include:

- Riveting, nut serts and other fastening systems

- Spot welding

- Inserts of studs, clinch nuts, bushes etc. using the Haegar Automatic Machine.

Painting and Powder Coating

We work closely with Trevon Industrial Finishers Ltd based in the North West who provides us with a range of coatings. This includes powder coating,

- Wet paint

- Powder coating

- Heat resistant coatings

- Chromate finishing on aluminium

With many years in the sheet metal industry we have built good working relationships with number other companies providing quality services in the following:

- Galvanising

- Plating

- Specialist Polishing

- Anodising

Enquire now

As a UK manufacturer our friendly team can help identify what you need and, if required, get it made. Give us a call - or send a message through the enquiry form and we’ll get back to you within 24 Hours.

Registered in England | Company Number: 04362198